Written by Capt. Caleb Langer

As a hose manufacturer, we spend a lot of time and attention focused on nozzle pairings, and so it is only fitting that we celebrate today, 7/8, or what our friends at Elkhart Brass have dubbed “The Day of the Nozzle.” The 7/8 smooth bore tip is referred to by many as “America’s tip”, and like fire departments from coast to coast, we are huge fans of this nozzle.

For perspective, it’s worth noting that it hasn’t always been this way. In the 1990’s and early 2000’s, many departments following the work of the late Andy Fredericks and other influential figures began to rediscover the effectiveness and simplicity of the smooth bore nozzle for handlines. The FDNY was undoubtedly the best known department employing solid streams for structural fire attack, and their use of the 15/16” tip in their small attack package (1-¾” nominal diameter hose) made that tip size nearly synonymous with “smooth bore nozzle” for early adopters—fire departments considering the switch during that era.

The wealth of knowledge and operational experience within the New York City Fire Department has rightfully earned them a tremendous degree of respect when it comes to matters of fireground tactics and equipment selection. When it comes to decisions impacted by staffing, however, such as the operation of handlines, very few of us find ourselves in the same position as the FDNY. Unless your department consistently staffs each engine company with an officer and four firefighters and marries two engine companies to support the deployment and operation of the first line, your decisions must reflect your operational reality.

(Elkhart Brass has a great Brass Tacks & Hard Facts with Curt Isakson speaking to the differences of the 7/8" and 15/16" tips. Watch it here.)

PAIRING YOUR NOZZLE TO YOUR STAFFING:

The matter of engine company staffing is where the 7/8 tip comes into play. A majority of the country puts two members on a handline, or three if they are lucky. In instances of necessity, two companies may be married to support the deployment of the first line, but this is typically the exception rather than the norm. In this light, it is necessary to consider which handline nozzle selection will best match your staffing.

A minimum target flow of 150 GPM has been considered an industry standard for many years, and studies by UL FSRI have confirmed the fire suppression abilities of this flow rate. The question arises: how can I meet or exceed this flow in a manner that works with my staffing?

KEEP THE NOZZLE REACTION FUNCTIONAL

It is broadly accepted that nozzle reaction should be kept to less than 70 lbs for a single firefighter at the nozzle, and many advocate for no more than 60 lbs in this situation. Given that a combination nozzle flowing the minimum flow of 150 GPM at 100 psi nozzle pressure exerts 76 lbs of nozzle reaction, the need to utilize a low pressure nozzle is apparent. At 50 psi, the 15/16 tip and the 7/8 tip produce 69 and 60 lbs of nozzle reaction, respectively, placing them both within the realm of consideration.

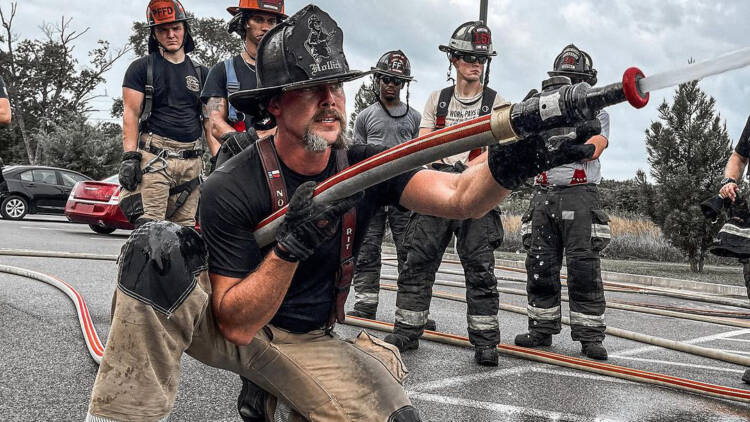

Any firefighter can operate a handline in excess of 70 lbs nozzle reaction by themselves in a stationary position. However, UL research has now validated the flow & move application as the gold standard for fire attack. Producing faster sustained cooling, decreased toxic gas concentration and improved oxygen levels, flow & move is better for both civilian fire victims and firefighters alike, improving survivability with each step taken on the advance.

FLOW & MOVE TO MAXIMIZE WATER

With the flow & move approach in mind, it has been repeatedly demonstrated that a two-person hose team will flow more water during the course of an advance with a 7/8 tip flowing 160 GPM, compared to an equivalent advance with the 15/16 tip flowing 185 GPM. This is due to the lower nozzle reaction of the 7/8 tip enabling fewer shutdowns and therefore more bale open time versus the 15/16. Any department wishing to validate this for themselves need only a training facility or acquired structure that replicates a standard residential advance, and a stopwatch or a flowmeter with a total flow feature.

While bale open time often gets the credit in the comparison of the two tip sizes, it pales in comparison to the impact of stream placement. UL has quantified placement in their study of water mapping, but any firefighter with time in the field has come to understand implicitly that only the water that reaches the spaces and surfaces it needs to cool has an impact on the success of the fire attack. Water that is not placed effectively has little value to the operation, regardless of flow rate.

"With the flow & move approach in mind, it has been repeatedly demonstrated that a two-person hose team will flow more water during the course of an advance with a 7/8 tip flowing 160 GPM, compared to an equivalent advance with the 15/16 tip flowing 185 GPM."

PLACE THE STREAM PROPERLY

Run the above drill again, this time observing effectiveness of stream placement during the advance, and the 7/8 will win even more definitively. No matter how good your nozzle firefighter, stream placement with less nozzle reaction will be superior to stream placement with more nozzle reaction. Add in fatigue and the obstacles of the fireground, and the nozzle producing less reaction force will allow the nozzleman to more reliably place the water where it is needed over the course of the advance.

PUMP THE PRESSURE PURPOSEFULLY

Although the fire service tends to view smooth bore handline nozzles as a fixed 50 psi operating pressure, some variation to this can be advantageous. For example, if a further reaching, harder hitting stream is required while operating in a stationary position (such as for multiple stories of porches on fire), the 7/8 tip can be over-pumped to 60 psi nozzle pressure, yielding 175 GPM. Conversely, under the right circumstances the 7/8 tip can also be under-pumped to 45 psi; this still yields a flow in excess of 150 GPM and provides adequate stream reach for the residential setting, but drops the nozzle reaction to a mere 54 lbs. This can be especially helpful for smaller or less experienced members, allowing them to flow & move more readily.

The 7/8 tip is effective, simple and reliable.

The solid bore allows it to clear debris without interfering with or compromising fire attack. Its large droplets yield gas contraction that exceeds steam expansion, and there is no “wrong” position caused by operator error or equipment malfunction, meaning that it will not create a condition that overpressurizes a compartment, regardless of how it is operated. The nozzle has few moving parts and has proven to hold up to the rigors of the fireground and the abuse of the training ground.

For the flow range and pressures discussed, the 7/8 tip pairs well with Mercedes ExoMetro for those preferring a lighter, more maneuverable, truer diameter 1-¾”. For those looking for lower friction loss and the more grounded feel of a larger diameter 1-¾”, it will also pair with our Kraken EXO 1-¾”. And for those looking to push boundaries, use of the HEN Turbo backpressure increaser even allows pairing with our KrakenEXO 1-½” hose.

No matter which of these lines you select, we are confident that you’ll find a high-performing attack package with America’s tip, the 7/8 smooth bore. Happy Day of the Nozzle!

About the Author:

Captain Langer joined the fire service in 1999 and has since worked for combination and career fire departments covering a range of response areas. He currently serves with the Northampton Fire Rescue Department (MA) where he holds the rank of Captain, having recently finished his tenure as the department’s training officer.

Caleb holds an A.S. in Fire Science from Greenfield Community College and is a graduate of Northeastern University’s Paramedic Program. His areas of focus in the fire service include engine company operations & water supply, fireground tactics and fire apparatus design, topics he has written on for Fire Engineering Magazine. He is rooted in a mission-oriented approach, dedicated to improving operational effectiveness.