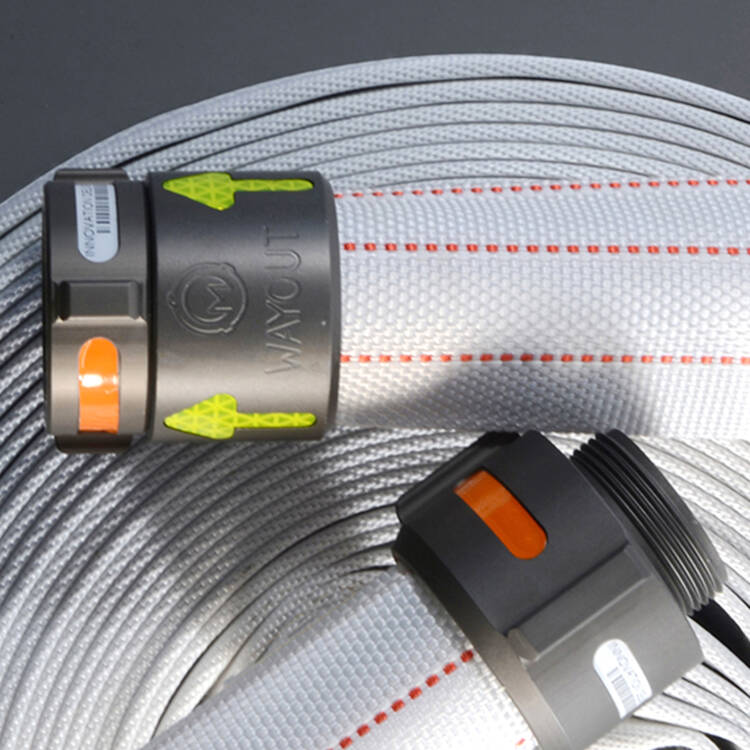

Carry-Lite® is designed to be the most easily advanced high rise attack and RIT hose – lightweight, yet rugged with the lowest drag coefficient. It is highly flexible and snag resistant due to unique inner bonding process of the outer jacket, which locks outer fibers in place. Available with our patented WAYOUT® couplings and IDentify® coding system.

| Specification | Imperial Measurement | Metric Measurement |

|---|

Both inner and outer jackets shall be made with high tenacity filament polyester yarn in both the warp and weft directions, to provide maximum strength and very snag resistant.

The outer jacket shall have a minimum of 10 filament polyester weft yarn picks per inch (394 per Meter) and when requested shall be impregnated in one of the standard NFPA colors with high performance polymeric dispersion.

Both the inner and exterior jackets shall be lined using polyurethane that must be applied using a fused process that welds the polyurethane directly to the textile while the hose is being woven, without the use of adhesives or hot melt.

The fused lining process must create a virtually inseparable unit without the use of adhesives, yielding an extremely low friction (pressure) loss by fi;ling in the corrugations of the weave, creating an ultra thin and smooth waterway. Fire hose made using adhesives of any type do not meet this specification. The lining shall be approved for use with potable water.

The adhesion shall be such that the rate of separation of a 1 ½” / 38mm strip of polyurethane, transversely cut, shall not be greater than 1/4” / 6mm per minute under a weight of 12 lbs / 5.5 kg.

A full length will withstand a hydrostatic pressure of 600 psi / 4140 kPa while kinked.

The female coupling shall have at least 3 reflective arrows, in order to be visible from any position. The reflective arrows must be engraved into and below the surface of the coupling, to resist abrasion. The arrows must point in the direction of the water source for a standard hose connection. The male coupling and female swivel nut must both have a recessed area to facilitate color and bar coding and/or identification markings.

Couplings shall be in conformance with the current NFPA standard and made of extruded aluminum, hard coated a minimum of .002” thick. They shall be manufactured in North America and permanently labeled with country of origin. They shall be expansion ring type.

WEIGHT

Each length of fi re hose shall not weigh more than indicated in the specification table.

COLD TEMPERATURE FLEXIBILITY

The hose must remain flexible to -65°F (-55°C).

SERVICE, TEST, BURST PRESSURES

Minimum service, test and burst pressures shall be as detailed in the specification table on the previous page.

MANUFACTURE

Both hose and couplings must be manufactured in North America.

Mercedes Textiles specializes in manufacturing premium double-jacket polyurethane fire hose. The inner jacket features our unique Mertex® lining — not EDM/rubber or nitrile — for unrivaled performance and superior quality.

From the hydrant to the nozzle, Mercedes manufactures both supply and attack fire hose in all standard sizes. We're known for our legendary KrakenEXO line, but we offer other quality lines for a variety of applications and priorities. We've got the hose you need, guaranteed.

All Mercedes hose and couplings are manufactured in North America.

Mercedes Textiles developed a patented weave process for our Mertex® inner hose linings. We weave a molten lining material directly into the fabric jacket at the loom. This offers a superior waterway — free from adhesives, glues or other bonding agents. The smoother surface minimizes turbulence and friction to deliver greater water flow at the discharge end. Mertex® lining also ensures your hose will never delaminate!

Mercedes Textiles' patented Breather™ Technology is an exclusive weave process that releases trapped air and water for superior packability, while also adding flexibility and strength. We currently incorporate these exclusive stripes into our large diameter hose MegaFlo® Breather and our newest KrakenEXO SUPER II™.

We take fire hose standards seriously – because YOU are on the line, and that matters to us. Mercedes is committed to ensuring every hose we manufacture meets or exceeds the latest NFPA 1960 (1961) standard. We have all the necessary testing equipment for each requirement, including the new UL-19 Radiant Heat testing required as of March 2021.

UL & ULC LISTINGS

On top of our own internal testing, we go above and beyond for many of our attack hose lines by submitting them to Underwriters Laboratory (UL) for third-party testing and approval. UL provides safety-related certification, validation, testing, inspection, auditing, advising and training services for fire hose products. Mercedes is world-renown for the premium quality, detailed specifications and superior performance of our fire hose.

FM APPROVAL

The international insurance carrier FM Global provides an independent testing division. Using scientific research and testing, FM Approvals make sure products conform to the highest standards for safety and property loss prevention. They follow five steps to make sure the products they’re testing meet quality guidelines. Products that pass get the “FM APPROVED” mark.

Mercedes takes pride in our products. We understand that a lot rides on their performance – from efficiency to safety. So when you have our lines, you can rest assured we have your back.

On most of our municipal products, we include either a 10-L and/or 2-10-L warranty – the best in the industry.

To install this webapp on your homescreen, tap and then Add to homescreen